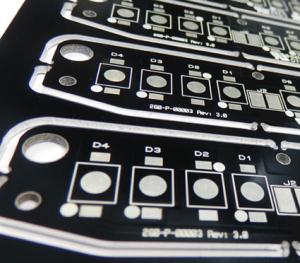

LED's and PCB's...

In recent years lighting designers have been moving rapidly towards LED technology to take advantage of the higher output and lower running costs that modern LED development offers. One obstacle with high output LED lighting is heat generation on the LED chip itself. If this heat is not efficiently transferred away from the light source the component will not perform to its optimum capability and will be prone to premature failure. Standard FR4 printed circuit board laminates are not thermally efficient and they are generally regarded as unsuitable where thermal management is required. IMS PCB’s are metal backed printed circuit boards, usually aluminium, with a thermally efficient, non-conductive dielectric layer bonded between the copper tracks and the aluminium substrate. This dielectric layer has a high ceramic content and allows the heat generated from LED dies and other high power driver components to transfer efficiently through to the metal substrate and away from the device itself allowing the components to run at optimal operational temperatures, elongating life and product reliability. For increased thermal efficiency the IMS PCB can be attached to a secondary heat sink if required.Cleveland Circuits manufacture and populate IMS PCB’s and have been supplying LED lighting and high power systems with IMS printed circuit boards for many years.

If you require Insulated Metal Substrate PCB's follow the the link below: